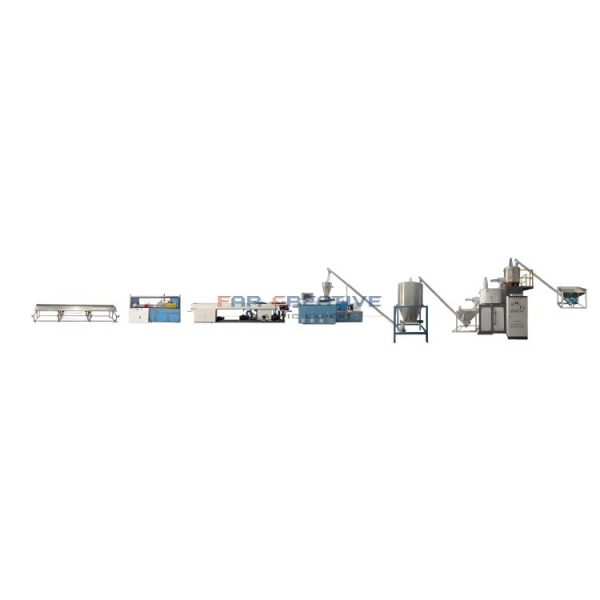

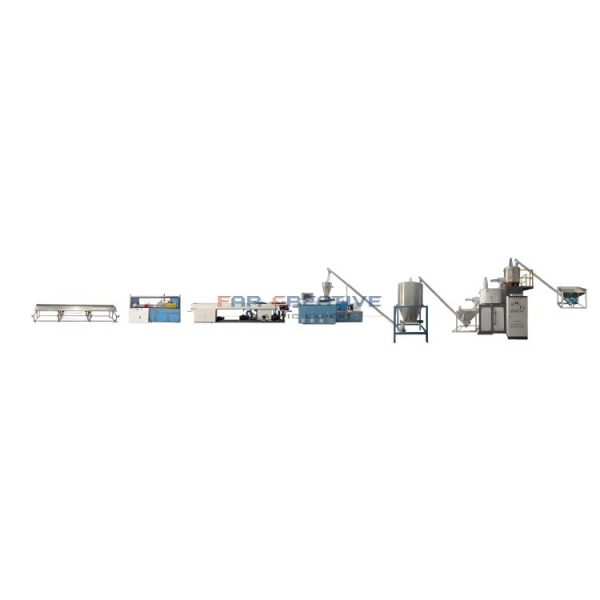

High-Efficiency PVC Twin Pipe Extrusion Line | Double-Strand Pipe Making Machine

- This high-efficiency PVC twin pipe extrusion line features a double-cavity mold for simultaneous extrusion of two pipes, ideal for manufacturing small-diameter PVC conduit and water pipes. The system includes an automatic loader, high-speed mixer, SJSZ65/132 conical twin-screw extruder, dual-pipe mold, vacuum calibration and cooling tank, integrated haul-off and cutter unit, and pipe stacker. Designed for increased productivity and reduced energy consumption in PVC pipe manufacturing.

- Direct supply from the manufacturer

- WhatsApp:+8618914915005

- Inquiry

Detail

|

1 |

Auto Loader |

1set |

|

2 |

High Speed Mixer |

1set |

|

3 |

Storage Silo |

1set |

|

4 |

65/132 Conical Twin Screw Extruder |

1set |

|

5 |

Double-Cavity Die |

1set |

|

6 |

dual-strand vacuum calibration and cooling tank |

1set |

|

7 |

dual-pipe haul-off and cutter integrated machine |

1set |

|

8 |

Stacker |

1set |

Product application

This PVC twin pipe extrusion line is mainly used for producing PVC pipes of various diameters and wall thicknesses for applications such as agricultural water supply and drainage, building water supply systems, and underground cable protection.

It is ideal for manufacturing small-diameter PVC conduit and water pipes. The production line features a double-cavity die, allowing two pipes to be extruded simultaneously, significantly increasing output and reducing energy consumption.

The complete extrusion system includes:

-

Material loader

-

High-speed mixer

-

SJSZ65/132 conical twin-screw extruder

-

Twin-pipe mold

-

Dual-strand vacuum calibration and cooling tank

-

Dual-pipe haul-off and cutter integrated unit

-

Pipe stacker

The screw extruder and haul-off unit are equipped with imported AC frequency inverters for precise speed control. Both the vacuum pump and traction motors are high-quality components, ensuring stability and durability.

The haul-off unit supports various traction configurations, including two-claw, three-claw, four-claw, six-claw, and eight-claw types, meeting the production needs of different pipe sizes and specifications.

Technical Parameter

| Specifications | |

|

Machine Model |

FCPL |

|

Processed material |

PVC |

|

Final product shape |

Pipe |

|

Output Range (kg/h) |

16-110 |

|

Diameter of screw |

65/132(standard) |

|

Voltage Standard |

According to the Voltage of the Customer's Location |

|

Warranty |

12 months from the date of bill of lading |

|

Technical services |

Project design, factory construction, installation and recommendations, commissioning |

Detail Information

1.Twin Screw Extruder

The extruder of PVC pipe line adopt high efficiency screw & barrel, notched feeding cylinder and is equipped with strong water jacket cooler, which greatly improves its transmission capacity and guarantees high-efficiency extrusion. the gearbox is hardening teeth gearbox with self-lubrication system. The motor adopt Siemens standard motor and speed controlled by ABB inverter. The control system adopts Siemens PLC control or button control.

2.Die Mould

Spacious flow channel design to guarantee high extrusion capacity and good melt.

Optimized temperature control and flow channel design, precise melt temperature control.

3.Vacuum calibration tank

The tank body of vacuum calibration tank adopt two chamber structure the vacuum calibration and cooling parts. Both of vacuum tank and spraying cooling tank adopt stainless steel 304.

The excellent vacuum system ensures the precise sizing for pipes, spraying cooling will improve the cooling efficiency, Auto water temperature control system make the machine more intelligent.

4.Haul-off Unit

For the different pipe size and different speed requirement, Far Creative developed kinds of haul-off unit accordingly.The haul-off unit equipped with single motor drive or every caterpillar with separate motor drive, there is the belt type haul-off unit, stable hauling.

For the large diameter pipe, a pipe winch device is equipped to the production line to reduced the waster material.

5.Cuttter

The high-speed, precise designed cutting machine is low in noise. And it is also equipped with strong scrap attracting device to reduce the work of maintenance to the lowest degree.

FAQ

Q: Is your company factory or trade company?

A: we are factory, we are engaged in this business for 15 years.

Q: Installation and stuff training available from you?

A: Yes, our engineers will guide machine installation and train your workers.

Q: What is the payment term?

A: The best way for both of us is 30% T/T deposit and 70% T/T balance payment before shipping, since we will test the machine before shipping. Of course, you can choose the way that more convenient (Payment terms: T/T, L/C, Western Union etc.)

Q: How about after service?

A:We can offer 12 months free warranty since the machinery arrived at your factory. We also offer space parts or repair service to our customer anytime and anywhere, we will send our technician to your factory if necessary.

Q: How to reach our factory?

A: It will take 40 minutes from Shanghai International Airport to our factory by car, and we will arrange our driver to pick you to our factory anytime.